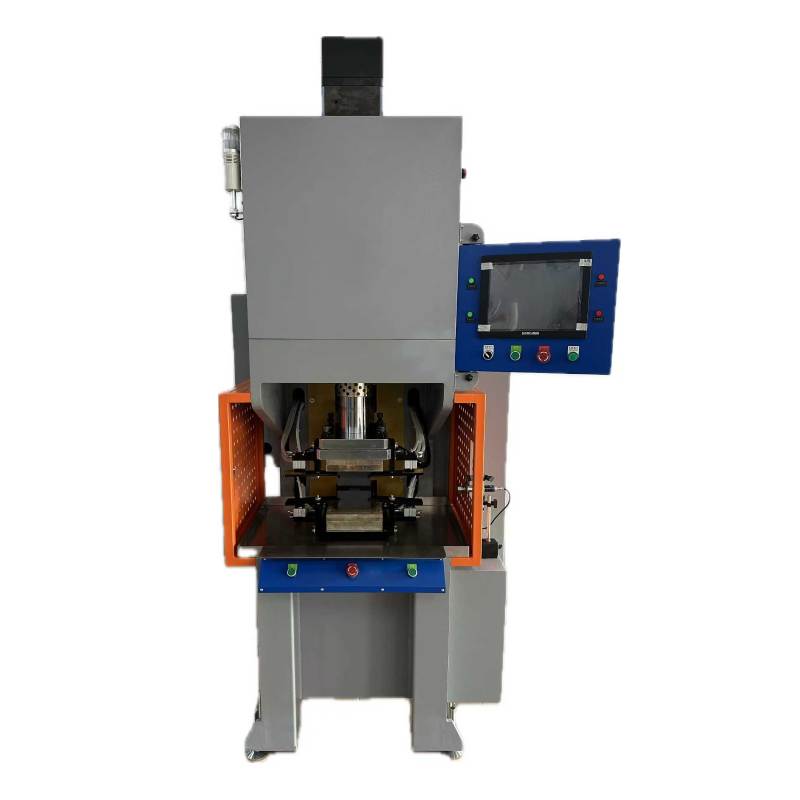

Servo electric cylinder copper polymer diffusion welding machine

| Item | Unit | Technical Specifications | ||

| Transformer capacity | KWA | 120 | 150 | 300 |

| Structural type | C-type servo electric cylinder lifting welding workbench | |||

| Control method | Frequency conversion inverter, industrial control system | |||

Temperature control range | ℃ | 0~1300 | 0~1300 | 0~1300 |

Work environment temperature | ℃ | -5~45℃ | -5~45℃ | -5~45℃ |

| Max. output pressure | Ton | ≤10 | ≤10 | ≤20 |

Workbench adjustable height | mm | ≤150 | ≤150 | ≤150 |

| Air source input pressure | Mpa | 0.5 ~0.8Mpa | 0.5 ~0.8Mpa | 0.5 ~0.8Mpa |

| Input power supply | Three-phase four-wire AC380V 50HZ 100A | Three-phase four-wire AC380V 50HZ 150A | Three-phase four-wire AC380V 50HZ 300A | |

| Welding area | mm² | 50*50*10mm (The smaller the area, the faster the speed.) | 70*70*10mm (The smaller the area, the faster the speed.) | 120*130*10mm (The smaller the area, the faster the speed.) |

Cooling water consumption | L/min | 150 | 240 | 350 |

| Electrode area | mm² | 200*200 | 200*200 | 200*200 |

Dimensions(L * W * H) | mm | 1400*1200*2400 | ||

Control Mode: This machine adopts an advanced touch screen + computer industrial control + human interface working method.

Usage: This machine is mainly used for the copper soft connections between battery modules of new energy vehicle battery packs (PACK), the copper soft connections for conductive connection of BDU, the air switches in the power system, the copper soft connections in the power bus ducts, and the copper soft connections for high current in electric locomotives.

Structure: C-shaped + four-column guide frame structure. It mainly consists of output transformers, frequency converters, industrial control system, servo cylinder pressure system, heating and temperature measurement control system, and current control system.